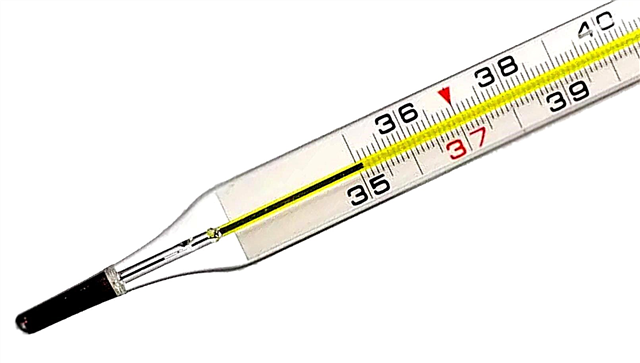

At all times, the extraction of mercury was not without loss for humanity. This is a metal that is hazardous to health and causes poisoning throughout the body. In industrial production, mercury is indispensable - it is the only liquid metal.

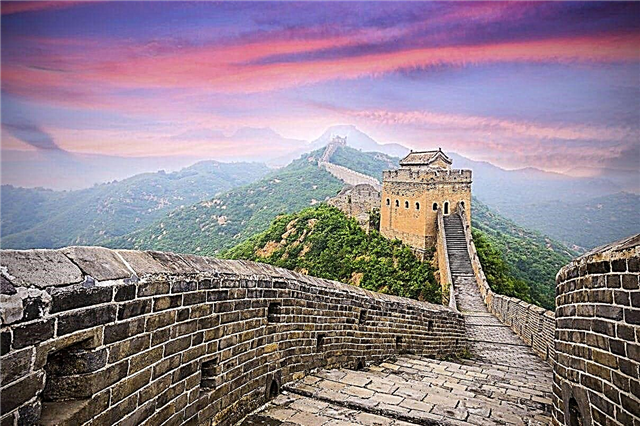

But interest in him has always been, especially among artisans in Central Asia. It was here that the first mercury mines appeared in the 6-4 centuries BC.

Where is mercury contained?

Metal is contained in a mineral called cinnabar - red stone, used since ancient times as a natural and high-quality dye. There are mercury in other mineral formations (approximately 20 items), but they contain little of this rare metal.

Features of mercury deposits

In industrial production, mercury is indispensable because it is the only liquid metal. There is no other such substance in fluid form at standard temperature with properties characteristic of metals. Therefore, its value is high and cinnabar is searched for in all countries.

From ancient China and India today, faith has come in the healing properties of this substance. There he was considered the blood of a dragon and imparted sacred qualities to the silver metal obtained from him. Over time, its healing properties have been confirmed by science. For all centuries, alchemists from the combination of mercury and sulfur tried to get gold, this significantly increased the value of the metal.

How to get mercury

Cinnabar contains more than 85% mercury sulfide, geologists do not know such another mineral rich in minerals. Mineral conglomerates are found in the form of granular or rhomboid fragments in rocks occurring at shallow depths. Mercury bodies are found in quartzite, dolomite and shale deposits. Mercury is extracted from the ore by heating, in which case it flows down from stone formations in small drops, which are collected in special protected tanks.

Development of mercury deposits

In mining practice, the development of mercury bodies is carried out in several ways.

- Underground mines. In them, the rock is crushed using explosions, then delivered to the surface. Extraction of the metal is carried out by oxidation-distillation roasting, in which mercury vapor is formed at high temperatures. The finished product is isolated from the gaseous phase to the condensate stage and collected.

- By the method of pumping in the adit of gases heated to 1000 degrees. This process causes the transition of the metal into the gas phase. Before starting the procedure, the sorbent is scattered in boxes with a bottom in the form of a grid and placed in an adit on racks. Then begins the cooling of the energy carrier, as a result of which the mercury-containing condensate precipitates on the sorbent. It is collected and sent to the factory to extract pure metal.

There are other mercury mining technologies, but all of them boil down to siphoning in the primary ore halos, introducing incandescent gas to form mercury vapor and a sorbent, which is then extracted with the mercury condensate accumulated on it and sent to the enterprise, where get the metal.

Which countries have industrial mercury deposits?

Significant mercury wealth lies in the bowels of several countries. This, Spain, Italy, China, Canada, Mexico, USA, Central Asia. Spain is the richest in mercury deposits, it accounts for 75% of the world's metal reserves and the largest mine is Almaden. It began to be developed more than two millennia ago.

In Russia, the main developments are underway in Transbaikalia, Kamchatka, Altai, and the Caucasus. Famous rich deposits of mercury are the mines of neighboring countries - Nikitovsky in Ukraine and Khaidarken in Uzbekistan (Ferghana Valley).